Description

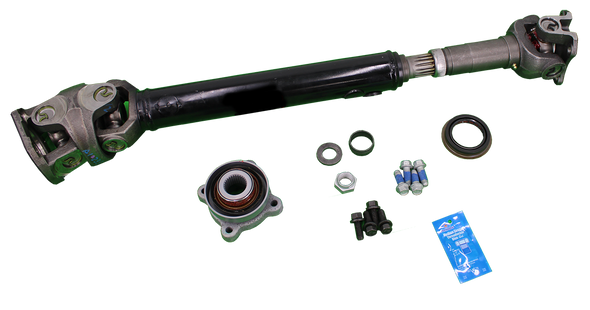

TK3134 Torque King® 1410 High-Angle Custom Front CV Driveshaft Assembly for 1999-2016 Ford Super Duty F250, F350 High Power and Lifted 4x4s with Dana 60/Super 60 Front Axles. We can supply a Custom Driveshaft featuring 1410 series 30° High Angle CV x 1410 Series Long Travel Slip Joint built to match YOUR truck. TK3134 includes everything you need for the upgrade including welded, balanced 1410HA Driveshaft with 1410 CV Head, 1410 Front U-Joint, Premium Lubed-for-Life U-Joints, Greaseable CV Ball, Long Travel Slip Joint, USA Made Drawn Over Mandrel (DOM) Driveshaft Tubing, 1410 Series Dana 60 Pinion Yoke, Pinion Seal, Crush Sleeve, Pinion Nut, Pinion Washer, (4) Grade 8 Bolts for the CV end, and Strap & Bolt Kit for the front u-joint. The Long Travel Slip Joint can collapse and extend beyond what your stock shaft could allowing for extreme axle articulation without the shaft bottoming out or pulling apart. For greater strength, we use USA made Drawn Over Mandrel (DOM) Driveshaft Tubing that is both stronger and more concentric than conventional welded tubing. Shaft is phased, welded, straightened, balanced and ready to install. Precision Assembled and finished in USA with both USA and imported parts. Note: TK3134 has a natural finish and is ready to install right out of the box or you can paint it with your favorite finish before installation.

We customize this shaft to your specific application. Please include the truck application in the Order Notes section of the check-out process or send us an email to: sales@torqueking.com. Include the order number in the email subject line. We need the length from the center of the flat flange on the transfer case to the center of the flat flange on the front axle. Your truck must have all 4 tires on the ground with full vehicle weight for an accurate measurement.

Need More Info? Use the handy Links below to access over 40 years of Dan's product and vehicle specific Tech Notes to easily get the information you need for your vehicle's repair, maintenance, or upgrade project!

Dan the Gear Man® Tech Notes:

U-Joint Specs

Check Fit

Pinion Yoke and Pinion Seal

Driveshaft Phasing

Driveshaft Straightening

Driveshaft Balance

Matching Parts

Applications

Tech Note 1: U-Joint Specs

All Three Universal Joints are made to Spicer 1410 series external snap ring dimensional specifications. The u-joint cup diameter is 1-3/16". The overall installed width is 4-3/16". Replacement U-Joint is QU40996. TK3134 uses u-Joints with Cold-Forged crosses. Most U-Joint crosses are forged by one of two methods, either hot-forged or cold-forged. Cold-forged crosses are harder and more resistant to wear, but the process is costly compared to hot-forging. Most u-joints with Hot-Forged crosses are greaseable and most u-joints with cold-forged crosses are not.

Tech Note 2: Check Fit

Our High Angle Series Driveshafts have Long Travel Slip Joints so typically the Tube length will be around 1/2" shorter than a factory driveshaft. However, the overall extended length of the driveshaft is 1" or more beyond the stock shaft. After installing your driveshaft, lower the vehicle so the full weight is on the suspension. Verify there is at least 1-1/4" of clearance between the slip yoke seal and slip stub face. If your driveshaft appears to be either too short or too long, CALL US before driving the vehicle!

Tech Note 3: Pinion Yoke and Pinion Seal

To provide initial lubrication for the seal, put a film of clean grease on both the pinion yoke hub and seal lips.

Tech Note 4: Driveshaft Phasing

Driveshafts need to be set in Phase during assembly. This means the yokes are ideally perfectly inline with each other. Our Driveshafts are made to adhere to the industry standard of +/- 2° Phase Difference or less.

Tech Note 5: Driveshaft Straightening

During assembly, the driveshaft parts are assembled to have the least possible runout. When a driveshaft is welded, the uneven heating and cooling of the shaft will usually cause the tube to warp slightly. We correct this by spot heating and cooling the shaft near the weld. On shafts that are not painted, you will often see a couple of round spots were the tubing is discolored by heat during the straightening process. The straighter the shaft, the less balance weights need to be used.

Tech Note 6: Driveshaft Balance

Our Driveshafts are dynamically balanced on specialized driveshaft balancing equipment before shipment.

Tech Note 7: Matching Parts

Matching Parts for TK3134 Front CV Drive Shaft:

QU90018 Pyroplex Plus Premium Synthetic Grease

QU90021 Spicer Life Ultra Premium Synthetic Grease

TM3000 Driveshaft Service Manual

QTA9405 Grease Gun Adapter for CV Grease Fitting

S9978 Medium Strength Threadlocker

Applications

Ford:

Customized to fit Super Duty F250 and F350 4x4 Trucks with Dana 60/Super 60 Front Axles: 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013, 2014, 2015, 2016

Warranty

Product Reviews

Delivery & Returns

Shipping times are estimated in your cart.

More info can be found at the link below.