Electric 4x4s and Light Trucks – Part 1: A Mechanics View

Electric 4x4s and Light Trucks – Part 1: A Mechanics View

April 1st, 2021

With the recent announcements by General Motors, Ford, and other vehicle manufacturers of upcoming electrically driven 4x4s and light trucks, we can expect electric power to start replacing the Internal Combustion Engine (ICE) in many popular 4x4 and light truck applications in the near future. How will the electrification of 4x4 and Light Truck drivetrains affect the 4x4 vehicle repair industry? The answer will vary by the type of electric drivetrain.

If we include hybrid 4x4 drivetrains like the recently released Jeep Wrangler 4xe, we have four possible ways to achieve electric motive power soon.

- 1. With the hybrid Jeep Wrangler 4xe, two auxiliary electric motors can power the vehicle by themselves or in conjunction with the gas engine. Other than the electric motors and 400-volt battery pack, the Wrangler 4xe drivetrain is conventional with a gasoline engine, automatic transmission, transfer case, driveshafts, and solid beam axles. Service for this type of drivetrain will not change significantly from current ICE-powered 4x4s except for the additional battery and electric drive components. A hybrid powertrain like the Wrangler 4xe is more complex and more expensive to make compared to most other engine and electric driven drivetrains with few of the advantages and many of the disadvantages of each. As a mechanic, I would love to see this type become mainstream, but chances are hybrid type drivetrains will only stay in production for a few more years unless battery technology and hydrogen fuel cell-powered vehicles do not advance significantly from today's level.

- 2. Battery Electric Vehicles (BEV) like Tesla makes would seem to be the way of the future, and they will IF major improvements in real-world range, battery weight, and recharging time become a reality. From a mechanic's standpoint, the big questions will be how many motors are used to drive the vehicle and where they are located. Different concept vehicles and near-production 4x4/light truck models use from one to four electric drive motors. By design, an electric drivetrain is much simpler than a conventional engine-driven one. With no engine, you eliminate 50% or more of vehicle service requirements. No tune-ups, timing belts, fuel systems, oil changes, exhaust systems or emission controls. That is a lot of out-of-work automotive technicians and huge savings for vehicle owners on maintenance expenses. However, with the 1, 2, 3, and some 4-motor powertrains, you will still need some type of driveshafts, separate wheel hub assemblies, and most likely some gearing, all of which will be similar to and require service like the same type of components in conventional drivetrains. The four-motor, direct-drive type like the Lordstown Endurance will have a direct drive hub motor at each wheel. With four direct-drive hub motors, almost every powertrain component used in an ICE-powered vehicle is eliminated, as will the need for automotive technicians to service engines/engine components, transmissions, transfer cases, driveshafts, and axles. If the use of the 4-wheel motor 4x4 drivetrain becomes widespread, most of today's automotive tech and mechanic jobs except suspension and steering will be obsolete. Yes, there will be some need for techs specializing in electric drivetrains and the cooling systems for them, but the simplicity of a battery-electric system with direct drive hub motors will mean far fewer automotive service jobs need to be filled compared to those needed for internal combustion engines.

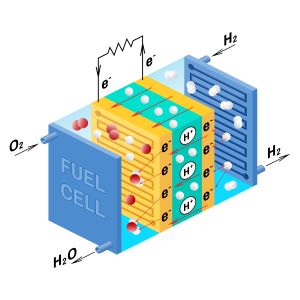

- 3. Hydrogen Fuel Cell Vehicles like the proposed Nikola Badger would seem to be the answer to almost all the drawbacks of both ICE and BEV vehicles with the long-range/cold-weather performance of ICE vehicles and the power/cleanliness of BEV. The hydrogen fuel system will undoubtedly require additional maintenance, plus the hydrogen piping and fuel system will have to be very durable. After decades of development, Hydrogen Fuel Cell power is still not quite ready for mainstream 4x4/light truck use, but if it ever gets there, the needed maintenance and service should closely parallel the different BEV drivetrains. The number of motors will largely determine the extent of required maintenance and repair.

- 4. Range extender drivetrains use an internal combustion engine to provide a longer range than a battery-only vehicle. These are similar in concept to the diesel/electric power units used in the U.S. Navy submarines all the way back to the 1930s. Essentially you take an electric vehicle with a motor(s) and battery pack and add an engine driving a generator for additional electric power as needed. From a repair and maintenance standpoint, you will still need engine service, but probably much less often than what would be required for a regular conventional engine-driven vehicle. Other repair and maintenance requirements will be similar to BEV vehicles and will depend upon the number and location of the drive motors.

In conclusion, electrification of 4x4s and light trucks will sooner or later completely reshape the vehicle service and repair business. From the employment standpoint, potentially hundreds of thousands of today's automotive technician jobs* and many repair businesses could be permanently eliminated. Some new jobs and business opportunities will be created, but the overall job loss will completely remake the automotive service sector. The speed of the change will essentially be dependent upon improvements in the range, weight, and recharge/refuel time of electric or hydrogen fuel cell technology. Unless there is a transformational change that provides double the range with longer battery life and less weight than today's best, you can expect the conventional internal combustion drivetrain to remain relevant for many years, especially in rural/mountainous/cold-weather regions where the current BEV range is inadequate for reliable, year-round transportation of both people and cargo.

*In the United States, as of 2019, there were 756,600 Automotive Service Technicians and Mechanics inspecting, maintaining, and repairing cars and light trucks, according to the U.S. Government Bureau of Labor Statistics. In addition to these jobs, there are many thousands of auto tech positions open due to a lack of qualified applicants.

Next Article will be about Electric Motors and Gearing

Latest News

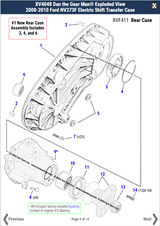

New Ford NV273F Transfer Case Exploded Views - Shop the FAST and EASY way!

New, Easy-to-Use, Interactive Ford Super Duty and Excursion Transfer Cases Exploded Views are connec...

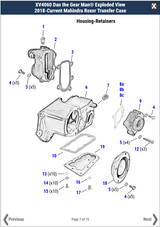

New Exploded View for 2018-Current Mahindra Roxor Transfer Cases!

New, Easy-to-Use, Interactive XV4060 Exploded View by Dan the Gear Man® for 2018-Current Mahindra...

NV5000 Manual Transmission Assembly for Dodge Ram 4x4s - Direct Replacement for NV4500HD

Available September 2024! A Direct Replacement for the NV4500HD - Upgrade today to the all new, c...

2003-2012 Ram NV271D Transfer Case Fluid and Torque Specifications, plus Recommended Mainteinance Schedule

The New Venture NV271D Manual Shift Transfer Case was the base transfer case for 2003-2012 Dodge and...

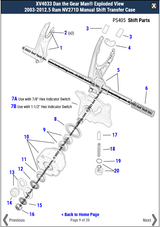

New Exploded View for 2003-2012.5 Dodge Ram Manual Shift NV271D Transfer Cases!

New, Easy-to-Use, Interactive XV4033 Exploded View by Dan the Gear Man® for 2003-2012.5 Dodge...

New Tools, Parts, Exploded Views, CAD Drawings, and Videos added in January 2023

We have added a number of new tools, parts, Exploded Views, CAD drawings, and videos to our websi...