- Causes of Manual Transmission Failures

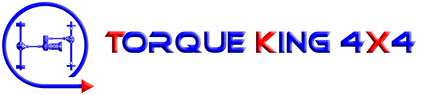

- 1957-1993 Dana 44 Solid Beam Inner Axle Seal Application List

- 1972-1993 Dodge Dana 60 Rear Wheel Bearing and Seal Application Chart

- 1972-1993 Dodge Van and Motorhome Dana 60 Rear Wheel Bearing Applications

- Dana 44 Differential Tech 1953-1993

- Defects in NV4500 Cast Iron Tailhousings

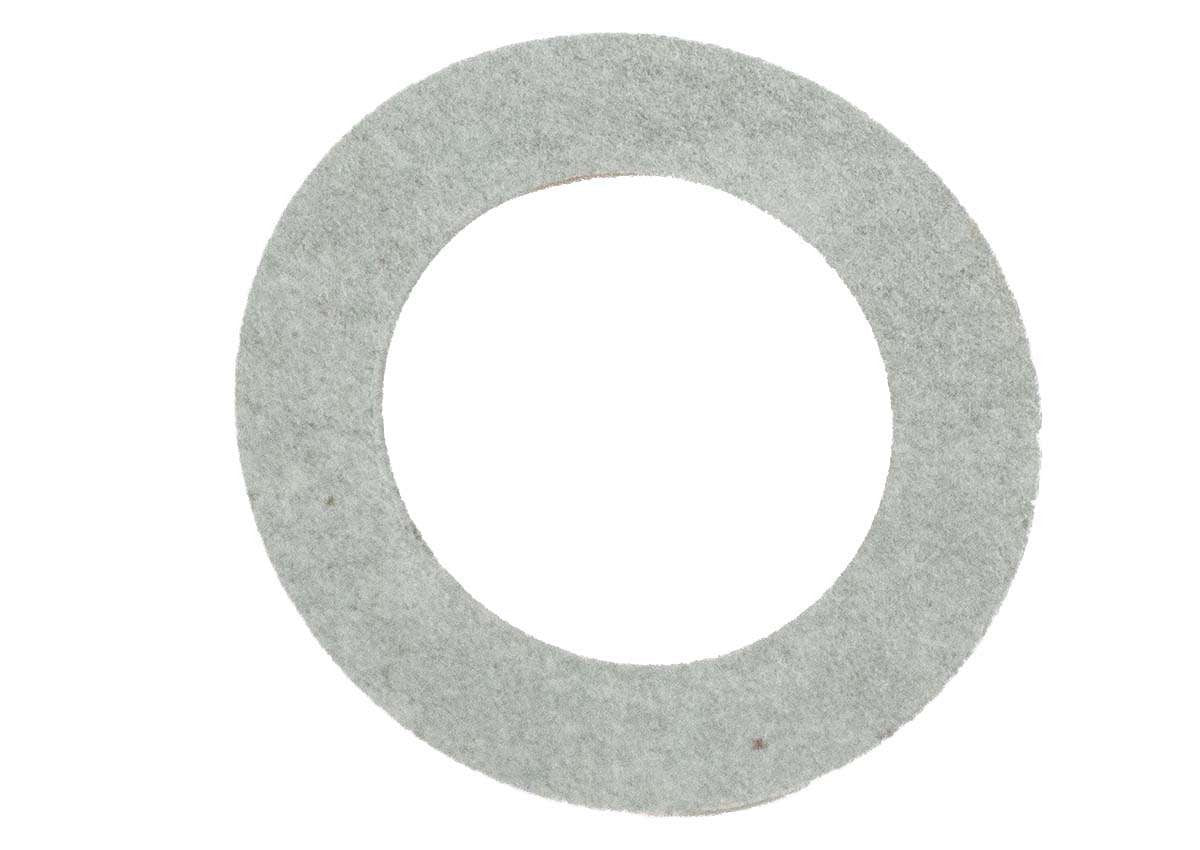

- Dodge & Ram Transfer Case Fluid Type

- Ford Full Size 4x4 Transfer Case Fluids

- Warn Premium Hub Applications

- Warn Standard Hub Applications

- New Video

- Dana Spicer Rear Drive Axle Component Failures

- NV4500 Transmission Problems & Solutions

- Short Ball Joint Life in 2003-2013 Dodge Ram AAM 925 Front Axles

- 1947-1959 Chevy & GMC NAPCO 4x4 Parts

- 1960-1966 Chevy Truck Parts & GMC C/K Series Parts

- 1967-1972 Chevy Truck Parts & GMC C/K Series Parts

- 1973-1991 GMC & Chevy Square Body Parts

- 1982-2004 Chevy S10 Parts & GMC S15 Parts

- 1988-2007 Chevy & GMC Truck Parts

- 2003-2009 Chevy Kodiak Parts & GMC TopKick Parts

- 2007-2019 Chevy Silverado Parts & GMC Sierra Parts

- 2018-Newer Silverado 4500, 5500, 6500

- 4th Gen Chevy Silverado & 5th Gen GMC Sierra Parts

- 1945-1971 Dodge Power Wagon Parts

- 1957-1971 Dodge D/W Series Truck Parts

- 1972-1993 Dodge D/W 100-350 & Ramcharger Parts

- 1987-2004 Dodge Dakota & 1998-2003 Durango Parts

- 1994-2001 Dodge Ram 1500 Parts

- 1994-2002 Dodge Ram 2500 Parts & 3500 Parts

- 2002-2019 Ram 1500 Parts

- 2003-2018 Ram 2500/3500/4500/5500 Parts

- 2005-2011 Dodge Dakota & 2004-2009 Durango Parts

- 2019-Current Ram 2500/3500/4500/5500

- 1954-1966 F250/350 & 1959-1965 Ford F100 Parts

- 1966-1977 Ford Bronco Parts

- 1966-1979 Ford F100/150 & 1978-1979 Bronco Parts

- 1967-1977 Ford F250 Parts & F350 Parts

- 1977-1979 Ford F250 Parts & F350 Parts

- 1978-2018 Ford Econoline Parts (E250/E350/E450)

- 1980-1997 Ford Truck Parts (F250/F350/F450)

- 1980-1996 Ford F150 Parts & Bronco Parts

- 1982-1997 Ford Ranger, Explorer & Bronco II Parts

- 1997-2014 Ford F150 Parts & Accessories

- 1999-2016 Ford Super Duty & Ford Excursion Parts

- 2017-Current Ford Super Duty Parts

- 1945-1964 Jeep CJ Parts

- 1946-1964 Willys Jeep Parts

- 1955-1971 Jeep CJ Series & Jeepster Commando Parts

- 1957-1965 Jeep FC Parts (FC-150 & FC-170 Models)

- 1962-1991 Jeep Wagoneer Parts & J-Series Parts

- 1967-1969 Jeep M715 Parts

- 1972-1986 Jeep CJ Parts & Jeep Commando Parts

- Jeep Wrangler YJ/TJ Parts & Jeep Cherokee XJ Parts

- Jeep Wrangler JK Parts & JK Rubicon Parts

- Jeep Wrangler JL Parts & JL Rubicon Parts

- New Tools from Torque King and QUAD 4x4

- Ball Joint Tools

- Bearing Cup Installers

- Ford Specific Tools

- GM Specific Tools

- IHC Specific Tools

- Jeep Specific Tools

- Dodge and Ram Specific Tools

- Roxor Specific Tools

- Front Axle Shaft Seal Tools and Kits

- General Tools

- Impact Sockets, Bits

- Transfer Case Tools

- Manual Transmission Tools

- U-Joint and DriveShaft Tools

- Wheel Bearing and Hub Tools