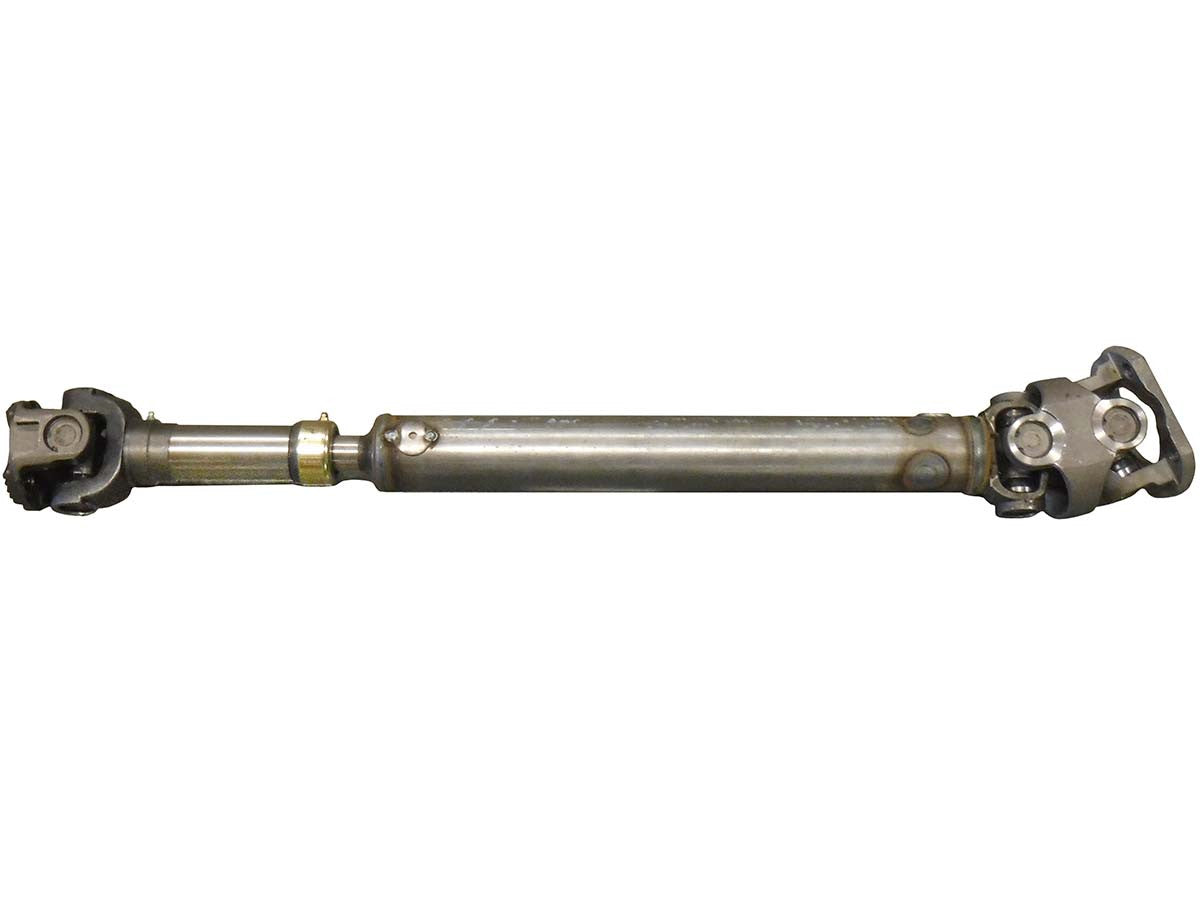

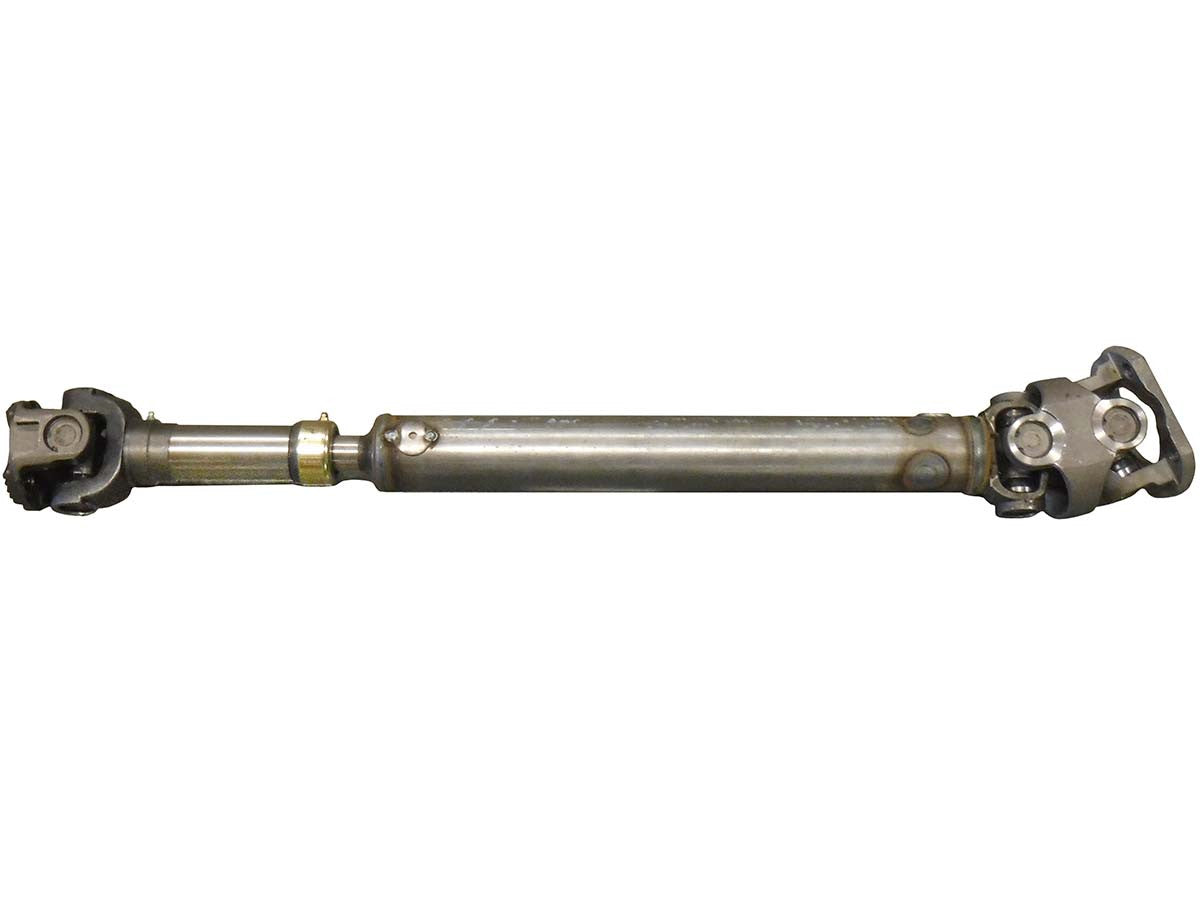

QU40964 Front CV Driveshaft for 2003-2005.5 Dodge NV5600 6 Speed

Built-to-Order -Usually ships in 3-5 business days

Description

QU40964 Silver 1350 Series Front CV Driveshaft for 2003-2005.5 Dodge Ram 2500, Ram 3500 with Cummins Diesel Engines and NV5600 6 Speed Manual Transmissions is a complete Flange to Flange assembly that features 0.095" special DOM Driveshaft Tubing, Non-Greaseable CV Ball, 1350 Series Greaseable CV U-Joints and Front U-Joint (3-5/8" wide x 1-3/16" cap diameter), Serrated Front Flange Yoke, and a Greaseable, Long-Travel (4-1/2"+) 1-3/8" x 16 Spline Slip Joint making it perfect for both stock and moderately lifted trucks of stock to moderate horsepower classes. Shaft is phased, welded, straightened, balanced and ready to install. Shipped unpainted. Assembled and finished in USA. Most component parts imported.

Need More Info? Use the handy Links below to access over 40 years of Dan's product and vehicle specific Tech Notes to easily get the information you need for your vehicle's repair, maintenance, or upgrade project!

Dan the Gear Man® Tech Notes:

U-Joint Specs

U-Joint Cross Material

U-Joint Sealing

Lubrication

Slip Joint Travel

U-Joint Angles

Driveshaft Tubing

Driveshaft Phasing

Driveshaft Straightening

Driveshaft Balance

Matching Parts

Applications

Tech Note 1: U-Joint Specs

All Three Universal Joints are made to Spicer 1350 series external snap ring dimensional specifications. The u-joint cup diameter is 1-3/16". The overall installed width is 3-5/8". Replacement U-Joint is QU40731.

Tech Note 2: U-Joint Cross Material

QU40964 uses u-Joints with Hot-Forged crosses. Most U-Joint crosses are forged by one of two methods, either hot-forged or cold-forged. Cold-forged crosses are harder and more resistant to wear, but the process is costly compared to hot-forging. Most u-joints with Hot-Forged crosses are greaseable and most u-joints with cold-forged crosses are not.

Tech Note 3: U-Joint Sealing

QU40964 uses greaseable u-joints that have a simple, single-lip seal that allows excess grease to be purged.

Tech Note 4: Lubrication

QU40964 has four lubrication points that can be greased with a standard grease gun. We recommend you Lubricate the universal joint periodically with QU90018 Pyroplex® Plus Synthetic Grease or other quality, water resistant NLGI #2 GC-LB grease. Each of the 3 Universal Joints has a standard grease zerk fitting in the cross. The Slip Yoke can be lubricated through a grease fitting located on the Slip Yoke Seal. By placing the lube point in the seal, excess grease will flow down the splines before it can exit out the vent on the yoke end. The CV Ball is not relubricatable. Service intervals for the greaseable universal joints and slip joint will vary with your driving conditions and type of grease you use, but as a minimum, you should grease your u-joints at every oil change or every three months whichever comes sooner. Lube more frequently in extremely wet conditions or after submersion under water. Remember, a greaseable joint that is not regularly lubed will prematurely fail from water contamination or grease loss. So, if you and your grease gun don't get together very often, we recommend you select one of our Platinum series Driveshafts with Sealed U-Joints.

Tech Note 5: Slip Joint Travel

The Slip Joint on a driveshaft expands and contracts as the axle articulates up and down. With the 2003-2013 Ram 2500 or Ram 3500 4x4, the vertical movement of the axle is in an arc due to the 4-link suspension arms. When the suspension is compressed, the axle is moved forward as the suspension arms become more horizontal. When the Suspension is extended the axle is moved rearward as the suspension arm angles increase. For the front driveshaft on a stock or near stock suspension truck driven mainly on smooth surfaces, the net result is movement of the slip joint is fairly small, as the axle moves up and forward, the driveshaft angle decreases. When the axle moves down, the driveshaft angle increases as the axle moves back. The two movements largely cancel each other out. The dynamics of Slip Joint movement change on rough terrain especially with lifted trucks which typically have a greater range of axle articulation. Our Silver Series Driveshafts have Long-Travel Slip Joints that can compress to about 1/2" less than stock and can safely extend at least 1" beyond stock lengths.

Tech Note 6: U-Joint Angles

On Ram 4x4 trucks with solid beam front axles, the driveshaft angle at the transfer case is greater than the angle between the driveshaft and front axle. The reason is simple, the engine, transmission and transfer case are angled down front to back several degrees. The front axle pinion is angled up. The difference can be as much as 10 degrees which is why a Double-Cardan front CV driveshaft is used. With stock suspension trucks, the CV Joint operating angle usually does not exceed about 15-16 degrees, however, with lifted trucks, the operating angle can exceed the design limits of the CV Joint. Also keep in mind the greater the angle, the less energy efficient the driveshaft is in transmitting power. As the angle increases an ever greater amount of power is used just to force the driveshaft through its rotation.

Maximum CV Joint Operating Angles for Ram Front CV Driveshafts:

1330 Series 18°

1350 Series 32°

1410 Series 22°

1410 Series High-Angle 30°

Tech Note 7: Driveshaft Tubing

Most factory and replacement Driveshafts use welded tubing which typically has a significant amount of ovality (not perfectly round) and bowing. Our driveshafts use Drawn Over Mandrel Special Driveshaft tubing which eliminates the heavy spot caused by the weld, is highly concentric and it is straightened to eliminate almost all bowing. Even better is our DOM tubing is stronger than welded tubing of the same size.

Tech Note 8: Driveshaft Phasing

Driveshafts need to be set in Phase during assembly. This means the yokes are ideally perfectly inline with each other. Our Driveshafts are made to adhere to the industry standard of +/- 2° Phase Difference or less.

Tech Note 9: Driveshaft Straightening

During assembly, the driveshaft parts are assembled to have the least possible runout. When a driveshaft is welded, the uneven heating and cooling of the shaft will usually cause the tube to warp slightly. We correct this by spot heating and cooling the shaft near the weld. On shafts that are not painted, you will often see a couple of round spots were the tubing is discolored by heat during the straightening process. The straighter the shaft, the less balance weights need to be used.

Tech Note 10: Driveshaft Balance

Our Driveshafts are dynamically balanced on specialized driveshaft balancing equipment before shipment.

Tech Note 11: Matching Parts

Matching Parts for QU40964 Front CV Drive Shaft:

QU70008 Bolt, Driveshaft to Front Pinion Flange

QU10806 Bolt, Grade 8 CV Driveshaft to Transfer Case Front Output Yoke

QU50727 Front Pinion Yoke

QU11012 Transfer Case Front Output Flange

TK11424 Gold Series 1350 Series All Greaseable Front CV Shaft

TK11425 Platinum Series 1350 Premium Front CV Shaft

TK3116 Platinum 1410 Series Front CV Driveshaft Kit

QU90018 Pyroplex Plus Synthetic Grease

TM3000 Driveshaft Service Manual

TM3318 Front CV Driveshaft Manual for 2003-2011 Dodge Ram 2500, Ram 3500

Applications:

Dodge and Ram:

Ram 2500, Ram 3500 with Cummins Diesel and NV5600 6 Speed Manual Transmission: 2003, 2004, 2005

Warranty

Delivery & Returns

Shipping times are estimated in your cart.

More info can be found at the link below.

QU40964 Silver 1350 Series Front CV Driveshaft for 2003-2005.5 Dodge Ram 2500, Ram 3500 with Cummins Diesel Engines and NV5600 6 Speed Manual Transmissions is a complete Flange to Flange assembly that features 0.095" special DOM Driveshaft Tubing, Non-Greaseable CV Ball, 1350 Series Greaseable CV U-Joints and Front U-Joint (3-5/8" wide x 1-3/16" cap diameter), Serrated Front Flange Yoke, and a Greaseable, Long-Travel (4-1/2"+) 1-3/8" x 16 Spline Slip Joint making it perfect for both stock and moderately lifted trucks of stock to moderate horsepower classes. Shaft is phased, welded, straightened, balanced and ready to install. Shipped unpainted. Assembled and finished in USA. Most component parts imported.

Need More Info? Use the handy Links below to access over 40 years of Dan's product and vehicle specific Tech Notes to easily get the information you need for your vehicle's repair, maintenance, or upgrade project!

Dan the Gear Man® Tech Notes:

U-Joint Specs

U-Joint Cross Material

U-Joint Sealing

Lubrication

Slip Joint Travel

U-Joint Angles

Driveshaft Tubing

Driveshaft Phasing

Driveshaft Straightening

Driveshaft Balance

Matching Parts

Applications

Tech Note 1: U-Joint Specs

All Three Universal Joints are made to Spicer 1350 series external snap ring dimensional specifications. The u-joint cup diameter is 1-3/16". The overall installed width is 3-5/8". Replacement U-Joint is QU40731.

Tech Note 2: U-Joint Cross Material

QU40964 uses u-Joints with Hot-Forged crosses. Most U-Joint crosses are forged by one of two methods, either hot-forged or cold-forged. Cold-forged crosses are harder and more resistant to wear, but the process is costly compared to hot-forging. Most u-joints with Hot-Forged crosses are greaseable and most u-joints with cold-forged crosses are not.

Tech Note 3: U-Joint Sealing

QU40964 uses greaseable u-joints that have a simple, single-lip seal that allows excess grease to be purged.

Tech Note 4: Lubrication

QU40964 has four lubrication points that can be greased with a standard grease gun. We recommend you Lubricate the universal joint periodically with QU90018 Pyroplex® Plus Synthetic Grease or other quality, water resistant NLGI #2 GC-LB grease. Each of the 3 Universal Joints has a standard grease zerk fitting in the cross. The Slip Yoke can be lubricated through a grease fitting located on the Slip Yoke Seal. By placing the lube point in the seal, excess grease will flow down the splines before it can exit out the vent on the yoke end. The CV Ball is not relubricatable. Service intervals for the greaseable universal joints and slip joint will vary with your driving conditions and type of grease you use, but as a minimum, you should grease your u-joints at every oil change or every three months whichever comes sooner. Lube more frequently in extremely wet conditions or after submersion under water. Remember, a greaseable joint that is not regularly lubed will prematurely fail from water contamination or grease loss. So, if you and your grease gun don't get together very often, we recommend you select one of our Platinum series Driveshafts with Sealed U-Joints.

Tech Note 5: Slip Joint Travel

The Slip Joint on a driveshaft expands and contracts as the axle articulates up and down. With the 2003-2013 Ram 2500 or Ram 3500 4x4, the vertical movement of the axle is in an arc due to the 4-link suspension arms. When the suspension is compressed, the axle is moved forward as the suspension arms become more horizontal. When the Suspension is extended the axle is moved rearward as the suspension arm angles increase. For the front driveshaft on a stock or near stock suspension truck driven mainly on smooth surfaces, the net result is movement of the slip joint is fairly small, as the axle moves up and forward, the driveshaft angle decreases. When the axle moves down, the driveshaft angle increases as the axle moves back. The two movements largely cancel each other out. The dynamics of Slip Joint movement change on rough terrain especially with lifted trucks which typically have a greater range of axle articulation. Our Silver Series Driveshafts have Long-Travel Slip Joints that can compress to about 1/2" less than stock and can safely extend at least 1" beyond stock lengths.

Tech Note 6: U-Joint Angles

On Ram 4x4 trucks with solid beam front axles, the driveshaft angle at the transfer case is greater than the angle between the driveshaft and front axle. The reason is simple, the engine, transmission and transfer case are angled down front to back several degrees. The front axle pinion is angled up. The difference can be as much as 10 degrees which is why a Double-Cardan front CV driveshaft is used. With stock suspension trucks, the CV Joint operating angle usually does not exceed about 15-16 degrees, however, with lifted trucks, the operating angle can exceed the design limits of the CV Joint. Also keep in mind the greater the angle, the less energy efficient the driveshaft is in transmitting power. As the angle increases an ever greater amount of power is used just to force the driveshaft through its rotation.

Maximum CV Joint Operating Angles for Ram Front CV Driveshafts:

1330 Series 18°

1350 Series 32°

1410 Series 22°

1410 Series High-Angle 30°

Tech Note 7: Driveshaft Tubing

Most factory and replacement Driveshafts use welded tubing which typically has a significant amount of ovality (not perfectly round) and bowing. Our driveshafts use Drawn Over Mandrel Special Driveshaft tubing which eliminates the heavy spot caused by the weld, is highly concentric and it is straightened to eliminate almost all bowing. Even better is our DOM tubing is stronger than welded tubing of the same size.

Tech Note 8: Driveshaft Phasing

Driveshafts need to be set in Phase during assembly. This means the yokes are ideally perfectly inline with each other. Our Driveshafts are made to adhere to the industry standard of +/- 2° Phase Difference or less.

Tech Note 9: Driveshaft Straightening

During assembly, the driveshaft parts are assembled to have the least possible runout. When a driveshaft is welded, the uneven heating and cooling of the shaft will usually cause the tube to warp slightly. We correct this by spot heating and cooling the shaft near the weld. On shafts that are not painted, you will often see a couple of round spots were the tubing is discolored by heat during the straightening process. The straighter the shaft, the less balance weights need to be used.

Tech Note 10: Driveshaft Balance

Our Driveshafts are dynamically balanced on specialized driveshaft balancing equipment before shipment.

Tech Note 11: Matching Parts

Matching Parts for QU40964 Front CV Drive Shaft:

QU70008 Bolt, Driveshaft to Front Pinion Flange

QU10806 Bolt, Grade 8 CV Driveshaft to Transfer Case Front Output Yoke

QU50727 Front Pinion Yoke

QU11012 Transfer Case Front Output Flange

TK11424 Gold Series 1350 Series All Greaseable Front CV Shaft

TK11425 Platinum Series 1350 Premium Front CV Shaft

TK3116 Platinum 1410 Series Front CV Driveshaft Kit

QU90018 Pyroplex Plus Synthetic Grease

TM3000 Driveshaft Service Manual

TM3318 Front CV Driveshaft Manual for 2003-2011 Dodge Ram 2500, Ram 3500

Applications:

Dodge and Ram:

Ram 2500, Ram 3500 with Cummins Diesel and NV5600 6 Speed Manual Transmission: 2003, 2004, 2005